turning residues into sustainable construction materials that store carbon dioxide forever

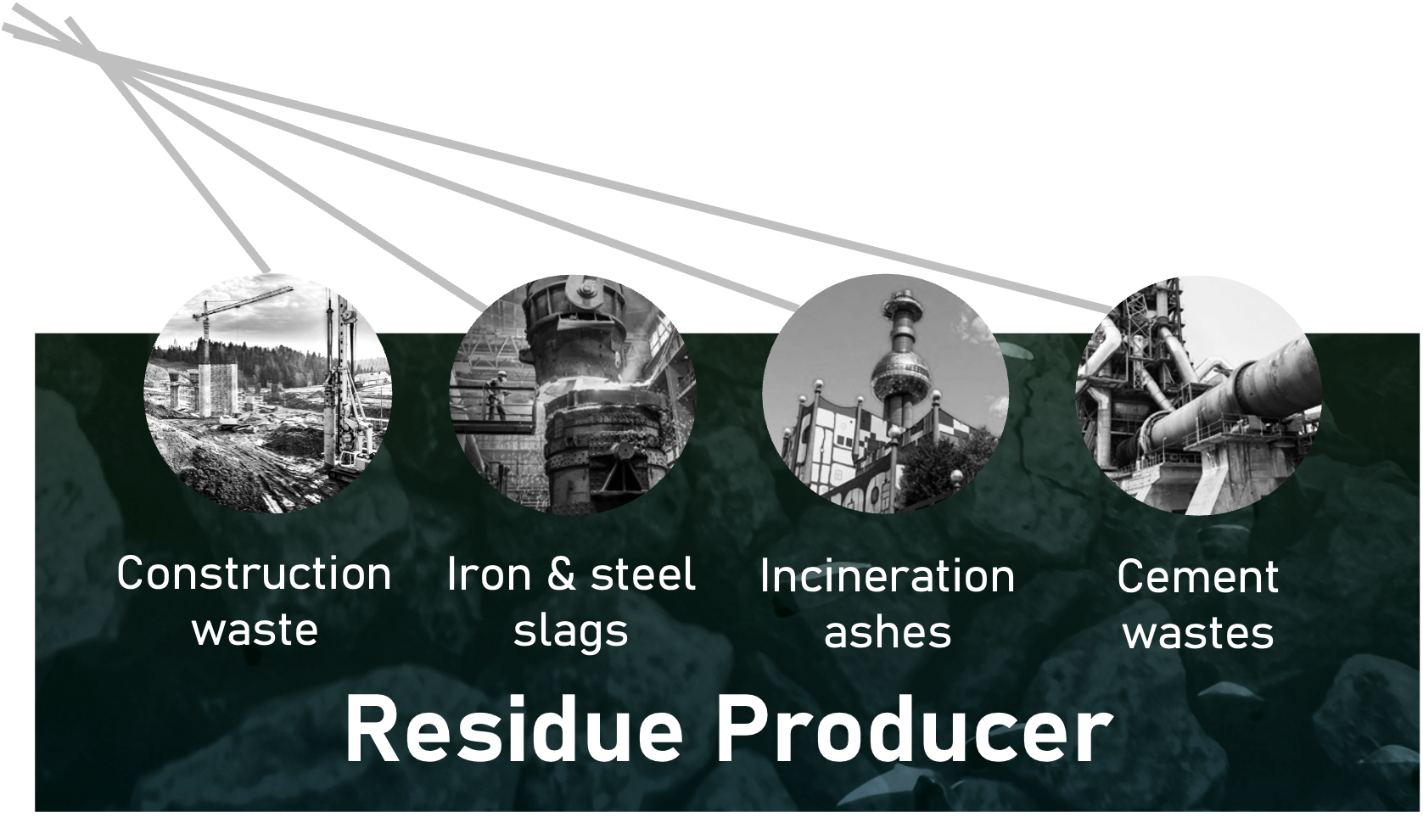

we enable customers to valorize their residues while reducing obligatory or issue voluntary carbon credits

carbon pricing is becoming a major cost driver for industry. By 2030, hard-to-abate sectors are projected to face €185B in EU ETS costs alone.

meanwhile, industries continue to landfill mineral residues at large scale. With tightening regulation and increasing landfill taxes, disposal costs are expected to rise sharply.

construction remains highly carbon-intensive, yet markets for low-carbon and sustainable materials are expanding fast.

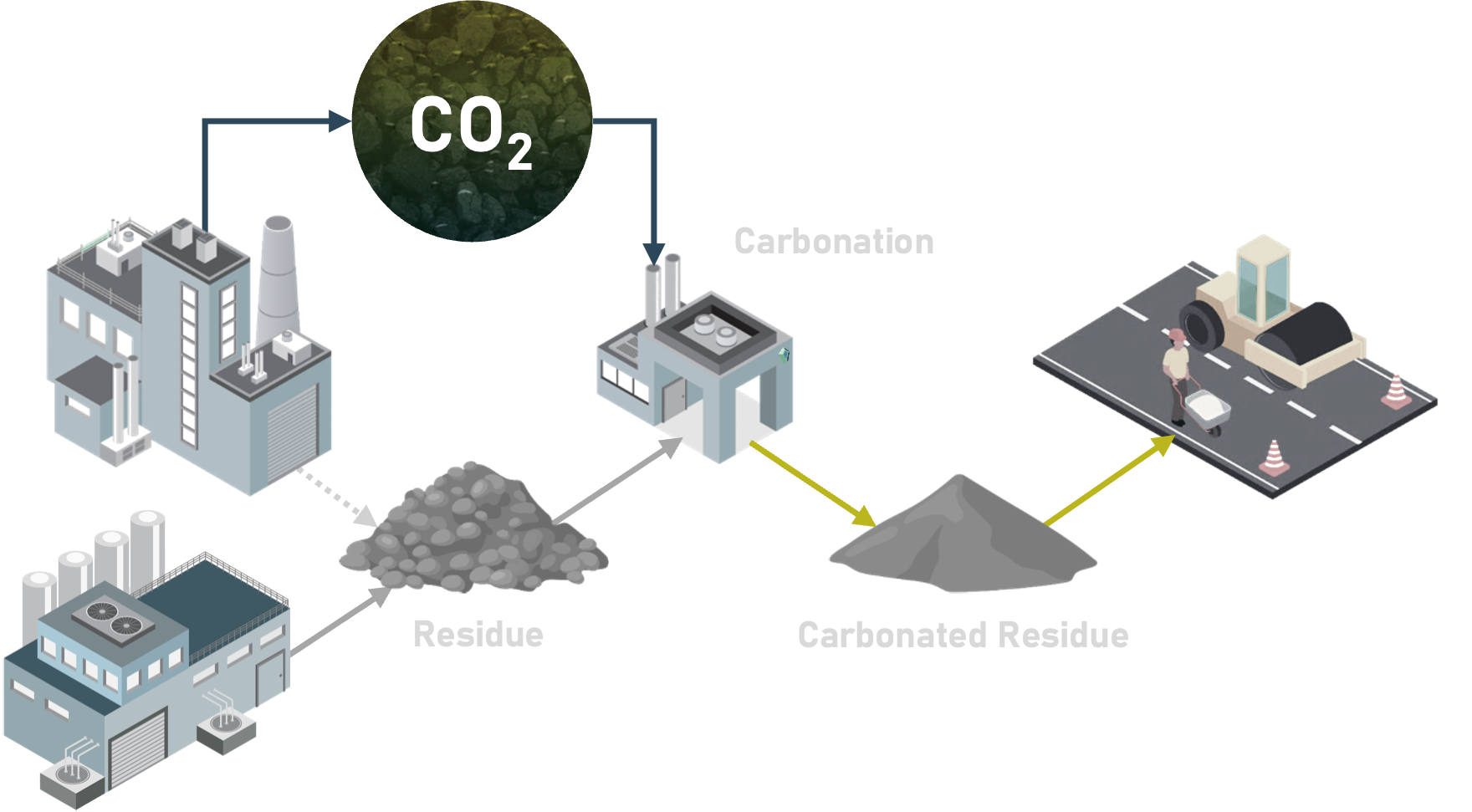

a cross-sectoral technology approach

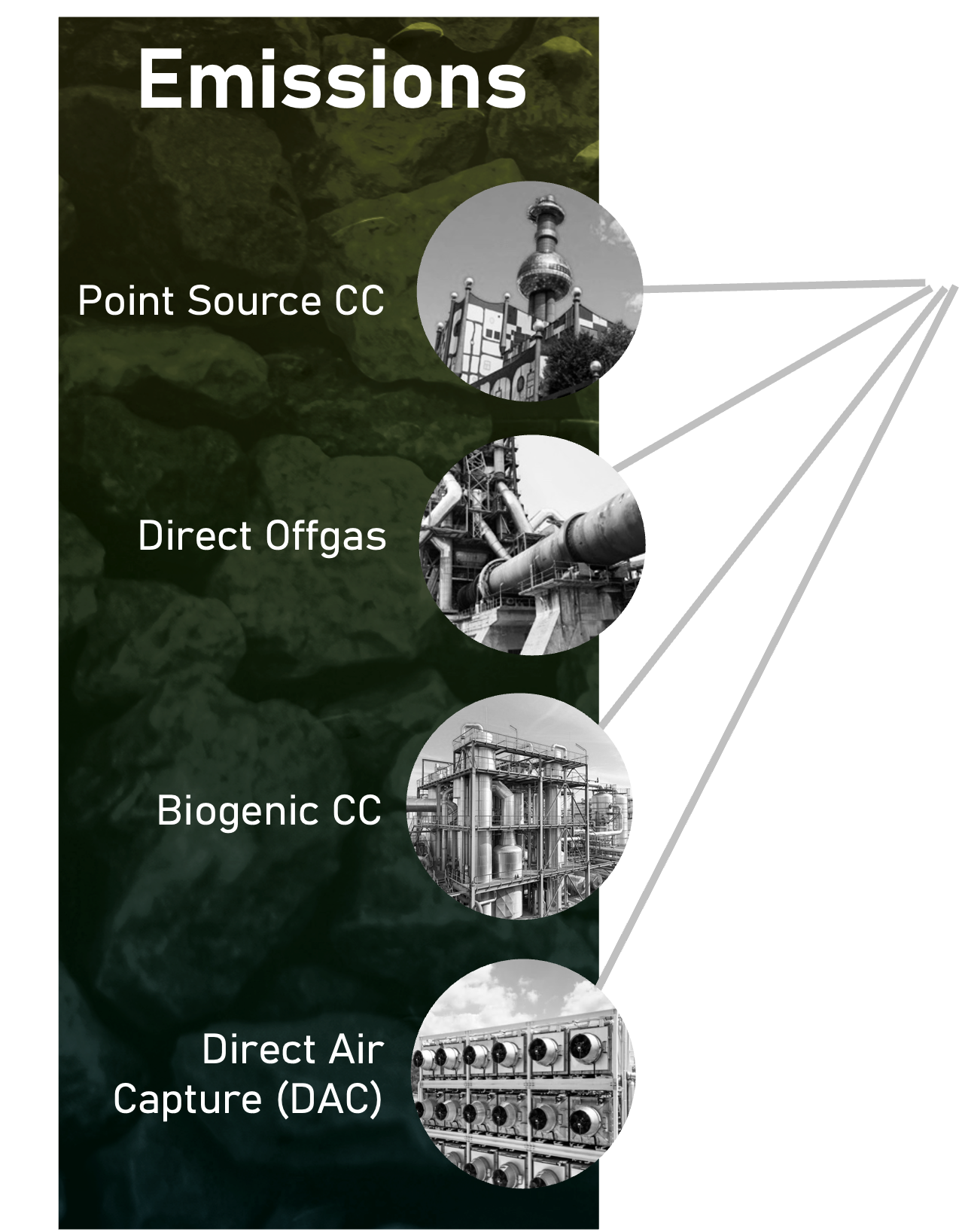

accelerated carbonation technology (ACT) permanently binds CO₂ from various sources in industrial residues.

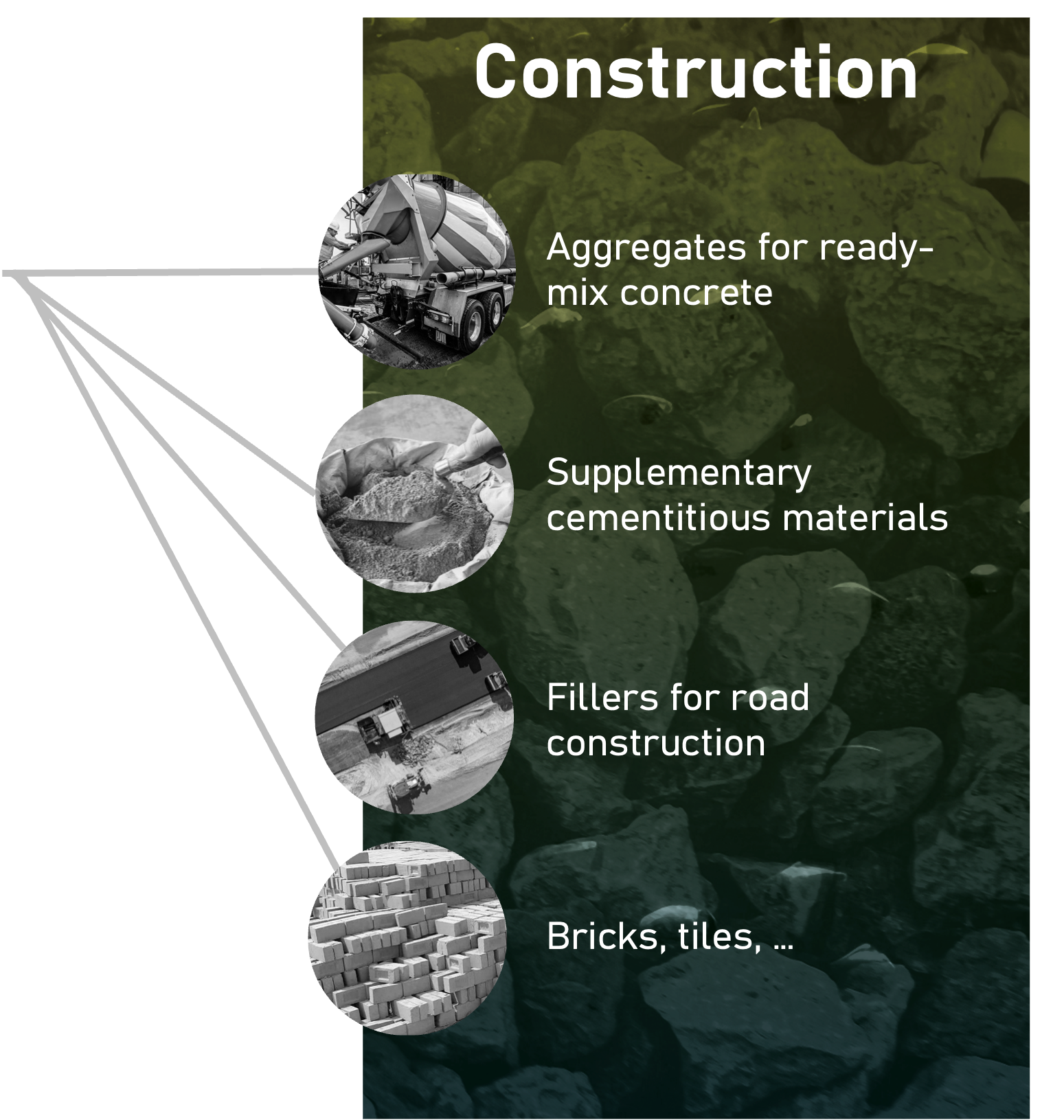

the carbonated output can be utilized in different construction applications and is the only EU ETS–approved form of CCU.

permanent carbon binding

depending on the material, ACT permanently stores up to 300 kg CO₂ per ton of residue, transforming costly waste streams into usable building materials.

Identifying the most suitable utilization pathway for each material is central to sequestra’s analysis.

our unique solution

sequestra is advancing a technology platform comprising material analysis, advanced data interpretation, and industrial carbonation plants equipped with in-house MRV. This unique platform combines to a one-stop-shop for CO₂ carbonation solutions.

our offer

sequestra starts with analytics-driven assessments and scales into industrial carbonation plants, covering the full path from feasibility to commercial deployment.

MATERIAL ANALYSIS

analyzing the practical CO₂-uptake potential in your mineral materials

BUSINESS CASE EVALUATION

assessing economic potentials, technical and legal implications of your specific business case

INDUSTRIAL REALIZATION

realizing pre-industrial pilot projects and

scale to commercial carbonation plants

what’s your material’s CO₂ binding potential?

our analysis technology allows standardized testing of small material samples under a great variety of different process parameters to identify their practically achievable CO₂-uptake.

1

you send a sample of your material

2

we carbonate your material under multi-parameter variation

3

you gain deep insights into

practical CO₂ uptake potentials

get in touch with us and discover how CO₂ can be mineralized in your materials.

office(at)sequestra.tech

our vision

globally, mineralizing industrial waste materials and using them as substitute of primary resources can reduce up to 4 Gt of CO₂ or 10 % of global emissions. The people behind sequestra are fully driven to unleash this potential and become a global frontrunner in this segment.

meet our founders

our founders combine a unique combination of +15 years of expertise spanning industrial plant construction, corporate sustainability strategy, and algorithmic optimization of complex recycling systems.

sequestra is backed by a world-class team of 16 skilled minds, with 92% engineering or science backgrounds across 8 nationalities.